Aussie Manufacturers

Moderators: collnarra, PeepeelaPew, Butts, beach_defender, Shari, sandonpoint, Forum Moderators

Aussie Manufacturers

I was wondering if there are any bodyboard manufacturers in Aust (not just importers) - i often read about you guys getting boards made for yourselves.

If so is it a big industry? (eg. turnover, quantity made in Aust etc)

The reason i ask is that there is a Duty Free Tariff Concession Order (TCO's) for bodyboards. these are generally only made when there are no local manufacturer, hence no "damage" to a local industry can be proven. I suspect that the local manufacturers (if any), wouldn't be aware of this (unless they read business and trade gazettes - unlikely). A TCO can be revoked if the local industry can prove "harm" as per above, and the import duty reinstated to help "protect" the local industry.

Obviously the imported boards will have a higher landed cost once a TCO is revoked.

Is the local product as good as the imported goods?

FYI - the surfboard industry has not allowed any duty free TCO's for imported surfboards.

If so is it a big industry? (eg. turnover, quantity made in Aust etc)

The reason i ask is that there is a Duty Free Tariff Concession Order (TCO's) for bodyboards. these are generally only made when there are no local manufacturer, hence no "damage" to a local industry can be proven. I suspect that the local manufacturers (if any), wouldn't be aware of this (unless they read business and trade gazettes - unlikely). A TCO can be revoked if the local industry can prove "harm" as per above, and the import duty reinstated to help "protect" the local industry.

Obviously the imported boards will have a higher landed cost once a TCO is revoked.

Is the local product as good as the imported goods?

FYI - the surfboard industry has not allowed any duty free TCO's for imported surfboards.

If it feels good, do it.

- Revolution

- Snowy McAllister

- Posts: 5063

- Joined: Wed Jun 27, 2007 11:34 pm

- Location: DY.CURL

Re: Aussie Manufacturers

Alot of brands are popped out of a workshop in bali.

There are also aus ones (although i dont know where most are) such as 4play / manta in cronulla...

Lambert will probably know more.

There are also aus ones (although i dont know where most are) such as 4play / manta in cronulla...

Lambert will probably know more.

Re: Aussie Manufacturers

interesting DeeseeDeesee wrote:I was wondering if there are any bodyboard manufacturers in Aust (not just importers) - i often read about you guys getting boards made for yourselves.

If so is it a big industry? (eg. turnover, quantity made in Aust etc)

The reason i ask is that there is a Duty Free Tariff Concession Order (TCO's) for bodyboards. these are generally only made when there are no local manufacturer, hence no "damage" to a local industry can be proven. I suspect that the local manufacturers (if any), wouldn't be aware of this (unless they read business and trade gazettes - unlikely). A TCO can be revoked if the local industry can prove "harm" as per above, and the import duty reinstated to help "protect" the local industry.

Obviously the imported boards will have a higher landed cost once a TCO is revoked.

Is the local product as good as the imported goods?

FYI - the surfboard industry has not allowed any duty free TCO's for imported surfboards.

Manta boards were made at kirrawee near cronulla and shifted to asia.

a few brands were at Tumbi Umbi on the central coast and Turbo are still ausie made i think.

Ill message a mate at turbo and tell him.

in the 90's there were quite a few local manufacturers. not so much anymore

Oscar Wilde - "I am not young enough to know everything"

Re: Aussie Manufacturers

not sure, Alistair Taylor custom ones were US, but they have teamed up with Turbo in Australia.Deesee wrote:If you want a Custom board, are they made local?

there were Toobs customs, NMD, Nick Mesritz Designs and a few others but to tell you the truth Deesee i don't know. its all changed so much since i really cared or looked at a mag.

now i just get a board from a mate that gets em cheep, don''t know where they come from.

the other guys on here might know, but i don't know much about the industry or shopping for boards and haven't for years. I just tell em i like the look of so and so board and ask for the same.

If you really want to know, Solid bodyboard shop or Emerald specialize in selling bodyboards and know all that stuff.

Oscar Wilde - "I am not young enough to know everything"

Re: Aussie Manufacturers

Nah he made them is South Africa. I've got one. They are very well made and because of the exchange rate, only $250AUD delivered. He has teamed up with Science now and him and Stewart are making some new boards.marcus wrote:Alistair Taylor custom ones were US, but they have teamed up with Turbo in Australia.

------------

BA (on Realsurf) wrote: It's the wild west with a bit more homo-eroticism.

Re: Aussie Manufacturers

I got a reply from Turbo

G'day Marcus,

Thank you for your email and the heads up re the TCO's.

To answer your question, yes Turbo does make hand made custom boards in Australia. There are not many companies that still do it. All the boards in the shops are made overseas because Australia cannot compete when it comes to operating costs (labour and factory rent).

If you reflect on the price of bodyboards, they are cheaper now than they were 15 years ago so once the shops take their cut there is no chance for Australian production.

The reality is that this is a broad issue across many industries and unfortunately the tariff is not enough to level the playing field when it comes to comparing costs of produuction with Asia. Our attitude is to support Australian owned companies that support the sport of Bodyboarding in Australia and keep the dream alive for groms. Our company employs 6 people in Australia and we have 3 professional Australian riders and many other groms that we support. We will always make our custom made boards in Australia in our Port Macquarie factory

Cheers

gregg

G'day Marcus,

Thank you for your email and the heads up re the TCO's.

To answer your question, yes Turbo does make hand made custom boards in Australia. There are not many companies that still do it. All the boards in the shops are made overseas because Australia cannot compete when it comes to operating costs (labour and factory rent).

If you reflect on the price of bodyboards, they are cheaper now than they were 15 years ago so once the shops take their cut there is no chance for Australian production.

The reality is that this is a broad issue across many industries and unfortunately the tariff is not enough to level the playing field when it comes to comparing costs of produuction with Asia. Our attitude is to support Australian owned companies that support the sport of Bodyboarding in Australia and keep the dream alive for groms. Our company employs 6 people in Australia and we have 3 professional Australian riders and many other groms that we support. We will always make our custom made boards in Australia in our Port Macquarie factory

Cheers

gregg

Oscar Wilde - "I am not young enough to know everything"

Re: Aussie Manufacturers

Cheers Marcus. I still reckon they could suss it out and at least attempt to make their competition pay the 5% import duty.

It goes both ways - if you guys are friends with board importers, check they're not being slugged Duty so they can add more coin to their pockets to put back into the sport.

Is turbo the same as the early 90's ones? My neighbour had a blue Mike Stewart board which was a Turbo (or Morey??). Anyway, i hope they make a superior local product which people will buy.

It goes both ways - if you guys are friends with board importers, check they're not being slugged Duty so they can add more coin to their pockets to put back into the sport.

Is turbo the same as the early 90's ones? My neighbour had a blue Mike Stewart board which was a Turbo (or Morey??). Anyway, i hope they make a superior local product which people will buy.

If it feels good, do it.

-

SURFFOILS.AU

- newbie

- Posts: 15

- Joined: Sun Jan 31, 2010 10:28 am

- Location: Gold Coast, Queensland

Re: Aussie Manufacturers

I ve been working on starting my own line of bodyboards since 08' but the only thing I didnt want to compromise on was where they were to be made.

I had a few contacts who said I could get the boards made in China very quick, very cheap but I was determined to have my boards made here in Australia. And its been a decision thats been hard to stick to.

I decided that instead of seting up my own factory, I'd outsource all the construction to specialised companies already set up to do the work, and initially it looked like I could put together a board for under $40 and retail it online at an amazing $60 but there were some costs I didnt see.

The boards have a core of FEPS or styrofoam and I like that foam because it has such a high bouyancy rating so you can use less volume and still float really well, and the first foam company said they could mould the foam cores with 4 full hard edged channels or any combo of concaves and Vee's for just $12.69 each ! And they could put out 500 boards a day... Bewdy, what a bargain I thought, but then they said the metal mould to do the job would be $ 25,000.....bummer, theres always a catch !

So I went to see how modern surfboards are made and although I have shaped a ton of boards over the years I needed to look at the modern shaping machines that all the big surfboard companies use these days. These shaping machines were rare a few years ago and located overseas where the labour was cheaper for mass production but now theres quite a few machines scattered all over Australia.

So I found a smart guy with a machine who wanted to do business, and now I can get cores cut from $20 blocks of specialised EPS and the shaping costs $35.

The cost for a SHAPED CORE only was going to be $12, now its $55 each. And I could get a complete board made overseas for $50 total.

But thats business in Australia,we've got the machines, the materials and the skilled people but the costs are almost beyond making a commercially viable bodyboard.

I'm still moving forward with the boards but theres no profit to be made, they will cost me about $150 each and I'll sell them for what they cost plus shipping.

As a money-making business, its not a success, but as a hobby to make an affordable high tech bodyboard with Australian labour, its possible. It a pity BBoard prices havent followed along with surfboard prices and making $10 on each board isnt enough to keep a business afloat, a reasonable profit needs to be at least $50.

The first run of boards are all but spoken for and it looks like I'll have orders mainly from overseas for more but we'll see what happens then, maybe there is a niche market for exotic boards or I might move on to something else.

You can follow where Im up to at http://surffoils.blogspot.com

Brett Curtis.

I had a few contacts who said I could get the boards made in China very quick, very cheap but I was determined to have my boards made here in Australia. And its been a decision thats been hard to stick to.

I decided that instead of seting up my own factory, I'd outsource all the construction to specialised companies already set up to do the work, and initially it looked like I could put together a board for under $40 and retail it online at an amazing $60 but there were some costs I didnt see.

The boards have a core of FEPS or styrofoam and I like that foam because it has such a high bouyancy rating so you can use less volume and still float really well, and the first foam company said they could mould the foam cores with 4 full hard edged channels or any combo of concaves and Vee's for just $12.69 each ! And they could put out 500 boards a day... Bewdy, what a bargain I thought, but then they said the metal mould to do the job would be $ 25,000.....bummer, theres always a catch !

So I went to see how modern surfboards are made and although I have shaped a ton of boards over the years I needed to look at the modern shaping machines that all the big surfboard companies use these days. These shaping machines were rare a few years ago and located overseas where the labour was cheaper for mass production but now theres quite a few machines scattered all over Australia.

So I found a smart guy with a machine who wanted to do business, and now I can get cores cut from $20 blocks of specialised EPS and the shaping costs $35.

The cost for a SHAPED CORE only was going to be $12, now its $55 each. And I could get a complete board made overseas for $50 total.

But thats business in Australia,we've got the machines, the materials and the skilled people but the costs are almost beyond making a commercially viable bodyboard.

I'm still moving forward with the boards but theres no profit to be made, they will cost me about $150 each and I'll sell them for what they cost plus shipping.

As a money-making business, its not a success, but as a hobby to make an affordable high tech bodyboard with Australian labour, its possible. It a pity BBoard prices havent followed along with surfboard prices and making $10 on each board isnt enough to keep a business afloat, a reasonable profit needs to be at least $50.

The first run of boards are all but spoken for and it looks like I'll have orders mainly from overseas for more but we'll see what happens then, maybe there is a niche market for exotic boards or I might move on to something else.

You can follow where Im up to at http://surffoils.blogspot.com

Brett Curtis.

Re: Aussie Manufacturers

Last edited by robzig on Tue Oct 18, 2016 10:18 am, edited 1 time in total.

-

dy_fo_life

- regular

- Posts: 143

- Joined: Wed Jun 22, 2005 10:08 am

- Location: schnaggletooth point

Re: Aussie Manufacturers

what about getting the tool made O.S but manufacturing at home....might get rid of the $25 000 start up?

-

SURFFOILS.AU

- newbie

- Posts: 15

- Joined: Sun Jan 31, 2010 10:28 am

- Location: Gold Coast, Queensland

Re: Aussie Manufacturers

DY_fo_life, I thought about that but my plan was to use Aussie labour where-ever I could. The mould from OS wouldve been about 6K instead of 25 so that wouldve been great if Id sourced it directly from China or similar.

But in the end I found out that if Id bought the mould here in Australia it wouldve been manufactured in Asia anyway, so the Aussie guys wouldve pocketed $19000 just for taking the order so it wouldnt have been made by Australians either way.

The way Im doing it now, the foam is blown in the western suburbs of Sydney in Banksmeadow, computer cut in Mona Vale and the rest of the boards parts are made in various places in Oz and assembled in Newcastle. Some of the basic things like stickering Im doing myself.

If I cared more about the money I wouldve been off on an Asian holiday touring the popout factories back in 08.

Silly me !

But in the end I found out that if Id bought the mould here in Australia it wouldve been manufactured in Asia anyway, so the Aussie guys wouldve pocketed $19000 just for taking the order so it wouldnt have been made by Australians either way.

The way Im doing it now, the foam is blown in the western suburbs of Sydney in Banksmeadow, computer cut in Mona Vale and the rest of the boards parts are made in various places in Oz and assembled in Newcastle. Some of the basic things like stickering Im doing myself.

If I cared more about the money I wouldve been off on an Asian holiday touring the popout factories back in 08.

Silly me !

Re: Aussie Manufacturers

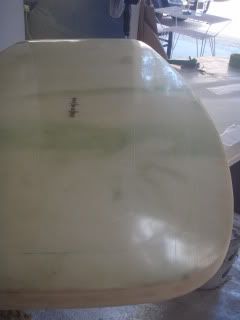

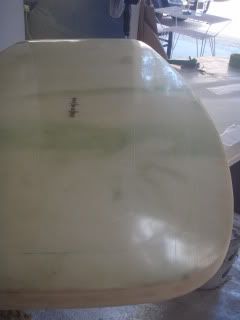

What type of foam are you using? Looks close to PU which is what surf boards makers use. Not like the large celled stuff like PE or PP that are used in Bodyboards.

------------

BA (on Realsurf) wrote: It's the wild west with a bit more homo-eroticism.

-

SURFFOILS.AU

- newbie

- Posts: 15

- Joined: Sun Jan 31, 2010 10:28 am

- Location: Gold Coast, Queensland

Re: Aussie Manufacturers

Because I was looking to build something new I considered all sorts of ideas for the boards overall construction, hollow, chambered, inflatable with a solid hull even solid wood, and I looked at a lot of construction techniques to test their strength and longevity. The last thing I wanted to do was sell something that fell apart.

The strongest surfcraft I found were the EPS cores with an ABS shell.

Its bulletproof and when I get a few test boards I'll belt them around and get it on video to show it takes a beating. The chance of your board warping or getting heavier is almost impossible with the ABS shell.

I had a look at all sorts of foams for the core, the amount the board flexes is more to do with the shell than the core so I didnt need to go with the standard PE or PP foams that are temperature sensitive.

There were some specialised foams I saw that were resilient but so expensive and the companies that sold them were temperamental too. And that really gives me the shits, these businesses that open their doors for business and then make business so difficult that its easier to walk away and give your money to someone else. Why they open their doors at all is a mystery !!!

Standard surfboard polyurethane foam was totally unsuitable so I chose the most modern version of EPS available. Its not cheap, but its mega light, easily shaped and uniformly responsive so each board has the exact flex, response and bouyancy as intended.

Theres no ply or plastic stringer/springers, strips of mesh, rods or tunnels drilled thru the core so its dependable.

The foam took a lot of research to find the right one but its the right one for this application. After the core is shaped its coated in a waterproof membrane and the shell is moulded around the core so the whole board bonds and moves as one piece.

We're still refining the whole process but when I get a few perfect boards I'll hand them out to some riders and a few magazines for review.

It'll be interesting to hear what the independant reviews are.

The strongest surfcraft I found were the EPS cores with an ABS shell.

Its bulletproof and when I get a few test boards I'll belt them around and get it on video to show it takes a beating. The chance of your board warping or getting heavier is almost impossible with the ABS shell.

I had a look at all sorts of foams for the core, the amount the board flexes is more to do with the shell than the core so I didnt need to go with the standard PE or PP foams that are temperature sensitive.

There were some specialised foams I saw that were resilient but so expensive and the companies that sold them were temperamental too. And that really gives me the shits, these businesses that open their doors for business and then make business so difficult that its easier to walk away and give your money to someone else. Why they open their doors at all is a mystery !!!

Standard surfboard polyurethane foam was totally unsuitable so I chose the most modern version of EPS available. Its not cheap, but its mega light, easily shaped and uniformly responsive so each board has the exact flex, response and bouyancy as intended.

Theres no ply or plastic stringer/springers, strips of mesh, rods or tunnels drilled thru the core so its dependable.

The foam took a lot of research to find the right one but its the right one for this application. After the core is shaped its coated in a waterproof membrane and the shell is moulded around the core so the whole board bonds and moves as one piece.

We're still refining the whole process but when I get a few perfect boards I'll hand them out to some riders and a few magazines for review.

It'll be interesting to hear what the independant reviews are.

Re: Aussie Manufacturers

Sounds great man. Flex is very important. Im keen to jump on one.

Are you sticking with a board traditional template?

Are you sticking with a board traditional template?

------------

BA (on Realsurf) wrote: It's the wild west with a bit more homo-eroticism.

-

SURFFOILS.AU

- newbie

- Posts: 15

- Joined: Sun Jan 31, 2010 10:28 am

- Location: Gold Coast, Queensland

Re: Aussie Manufacturers

I couldve just copied any popular board design and whacked my own logo on it, but thats a bit shallow/lazy/illegal so I had a look at the hydrodynamics of all types of surfcraft as well as my own history of board making, I made my first one in 1972.

Bodyboards are a unique shape to begin with, they have a minimalist design that has a set of basic essentials that are almost perfect for almost every wave....

1. A flat hard slick

flat for speed,

hard so it can handle the scrapes of use

2. minimal nose rocker

The nose needs some type of rocker to reduce 'digging in' and combined with the pulled in outline of the nose, it keeps the front loose and easy to control without pearling.

3. Soft foam body.

Soft foam makes a bodyboard light to carry, store and travel with, comfortable to ride, appealing for parents to buy because its seen as safer than fibreglass, and foam gives the board flex, which apart from all the performance possibilities, gives the board longevity in the surf environment. Foam is also easier to shape and heat weld than laying up sloppy fibreglass resins and then sanding away to smooth it out.

So these elements make for a product that has great consumer appeal and easy control but it has its limits and the main one is that the standard design doesnt turn.

Yes they can turn but after watching BB riders take thousands of waves, the standard ride consists of,

1.takeoff

2. going straight, straight, straight

3 pull into closeout/rollo or foam bounce.

Thats not on every wave but its the 95% average for sure.

The average standup surfer learns to turn and link turns and turns become the challenge to rip the most number of extreme slashes all over the wave.

But not for bodyboards.

So the one thing I focussed on developing in my design was to give the board the ability to turn and hold, turn at slow speeds, to do real cranking bottom turns like a surfboard,snap under the lip, where-ever you want.

The basic flat bottom design of BBs give it the best speed in the water but if a bodyboard could turn like a surfboard, it would open up the possibilities for different manouvers and to get more out of every wave.

And after making a ton of prototypes...

I changed a few things, and kept some of the basics too.

I kept the flat bottom, great for speed...

I kept the angled rails but lowered the apex and rolled the deck so the board rolls easier in and out of turns.

And I sharpened up the nose so it has less weight..

the front of the board is tapered for graduated flex...

And the front edge is better designed to pull thru the wave and spear thru foam, it looks a bit more agressive without being dangerous.

But the major variation is in the planshape, the wide point has come back further but the performance benefits by doing this are also new. Having the WP back allows the board to skate along on the flat hull but when tilted the weight of the rider pushes the thinner rail into the wave face and the board pivots off the WP like it had fins.

The nose is the same width but the pulled in outline at the front makes the board so easy to turn up the face and snapp from the back of the board.

Its different, but its a mix of the old basics that work and upgrades to areas that improve the performance without taking away from the bodyboard feel.

Bodyboards are a unique shape to begin with, they have a minimalist design that has a set of basic essentials that are almost perfect for almost every wave....

1. A flat hard slick

flat for speed,

hard so it can handle the scrapes of use

2. minimal nose rocker

The nose needs some type of rocker to reduce 'digging in' and combined with the pulled in outline of the nose, it keeps the front loose and easy to control without pearling.

3. Soft foam body.

Soft foam makes a bodyboard light to carry, store and travel with, comfortable to ride, appealing for parents to buy because its seen as safer than fibreglass, and foam gives the board flex, which apart from all the performance possibilities, gives the board longevity in the surf environment. Foam is also easier to shape and heat weld than laying up sloppy fibreglass resins and then sanding away to smooth it out.

So these elements make for a product that has great consumer appeal and easy control but it has its limits and the main one is that the standard design doesnt turn.

Yes they can turn but after watching BB riders take thousands of waves, the standard ride consists of,

1.takeoff

2. going straight, straight, straight

3 pull into closeout/rollo or foam bounce.

Thats not on every wave but its the 95% average for sure.

The average standup surfer learns to turn and link turns and turns become the challenge to rip the most number of extreme slashes all over the wave.

But not for bodyboards.

So the one thing I focussed on developing in my design was to give the board the ability to turn and hold, turn at slow speeds, to do real cranking bottom turns like a surfboard,snap under the lip, where-ever you want.

The basic flat bottom design of BBs give it the best speed in the water but if a bodyboard could turn like a surfboard, it would open up the possibilities for different manouvers and to get more out of every wave.

And after making a ton of prototypes...

I changed a few things, and kept some of the basics too.

I kept the flat bottom, great for speed...

I kept the angled rails but lowered the apex and rolled the deck so the board rolls easier in and out of turns.

And I sharpened up the nose so it has less weight..

the front of the board is tapered for graduated flex...

And the front edge is better designed to pull thru the wave and spear thru foam, it looks a bit more agressive without being dangerous.

But the major variation is in the planshape, the wide point has come back further but the performance benefits by doing this are also new. Having the WP back allows the board to skate along on the flat hull but when tilted the weight of the rider pushes the thinner rail into the wave face and the board pivots off the WP like it had fins.

The nose is the same width but the pulled in outline at the front makes the board so easy to turn up the face and snapp from the back of the board.

Its different, but its a mix of the old basics that work and upgrades to areas that improve the performance without taking away from the bodyboard feel.

Re: Aussie Manufacturers

very interesting surfoils. i would love to try some of your boards out.

Oscar Wilde - "I am not young enough to know everything"

-

SURFFOILS.AU

- newbie

- Posts: 15

- Joined: Sun Jan 31, 2010 10:28 am

- Location: Gold Coast, Queensland

Re: Aussie Manufacturers

Thanks Marcus and Ron, taking a board from design to market takes more work than would initially seem.

A new design, if you want it to be appealing, has to also look similar to whats on the market. I couldve brought out an incredibly futuristic looking slice of board design with concaves, rail grooves and all sorts of new features but it wouldnt have been accepted, just too far 'left field' for most people.

So I started out with the best design that pushed into new levels of performance, and then toned it down, step by step until it became a transitional shape between established and new.

It had to resemble whats in the shops now but still offer something new, so it wouldnt look odd but it would deliver when ridden. Ive read lots of marketing about how "brand X" is 'bringing it' with this seasons cutting edge boards but in the end, it was just hype. But whether my boards are liked or not , they do deliver something new for people who want it.

And when it comes to manufacturing the board I have to find a series of suppliers who not only have the right materials but who are easy to deal with, keen to work and able to do something new. You'd think if someones got a warehouse full of stuff and I'm trying to buy it, it'd be easy , yes ? Ive had to kiss arse, hand out cases of beer to smooth the waters, and pay what ever the price because if one person turns me down theres often no alternative manufacturers in Australia.

Im not going to name names but its not easy to find people that listen and think and will work together. I suppose Ive spent hundreds of hours, maybe thousands, over the past 2 years just working on one design and finding the right team to put the boards together. But the team is working smoothly now, the right people are working in the right direction and the boards will be perfect when theyre done.

yes Ron, there has to be a good margin on boards or else they'd all be made OS, so any local manufacturers deserve your support.

Theres only 2 ways of making a quid with a product, you either sell low volume with huge profit or

huge volume with small profit.

For small board manufacturers the cost of materials are often high and inflexible, labour is usually done by the business owner/s and theres a storm of unavoidable government taxes, fees and charges that cripple any chance of making a profit so how anyone (apart from the big names) make a dollar in this industry is a mystery.

For me, this is something Ive always wanted to do,I'll make the first run of 50 boards and after that I'll only make as many as are ordered. I can avoid a lot of the government grief if I do this as a non profit hobby so thats my approach, as long as it doesnt send me broke I'll keep making boards.

And if I dont get any orders, you'll find me in the Coolangatta pub.( The Cruel Sea are playing 6th March )

A new design, if you want it to be appealing, has to also look similar to whats on the market. I couldve brought out an incredibly futuristic looking slice of board design with concaves, rail grooves and all sorts of new features but it wouldnt have been accepted, just too far 'left field' for most people.

So I started out with the best design that pushed into new levels of performance, and then toned it down, step by step until it became a transitional shape between established and new.

It had to resemble whats in the shops now but still offer something new, so it wouldnt look odd but it would deliver when ridden. Ive read lots of marketing about how "brand X" is 'bringing it' with this seasons cutting edge boards but in the end, it was just hype. But whether my boards are liked or not , they do deliver something new for people who want it.

And when it comes to manufacturing the board I have to find a series of suppliers who not only have the right materials but who are easy to deal with, keen to work and able to do something new. You'd think if someones got a warehouse full of stuff and I'm trying to buy it, it'd be easy , yes ? Ive had to kiss arse, hand out cases of beer to smooth the waters, and pay what ever the price because if one person turns me down theres often no alternative manufacturers in Australia.

Im not going to name names but its not easy to find people that listen and think and will work together. I suppose Ive spent hundreds of hours, maybe thousands, over the past 2 years just working on one design and finding the right team to put the boards together. But the team is working smoothly now, the right people are working in the right direction and the boards will be perfect when theyre done.

yes Ron, there has to be a good margin on boards or else they'd all be made OS, so any local manufacturers deserve your support.

Theres only 2 ways of making a quid with a product, you either sell low volume with huge profit or

huge volume with small profit.

For small board manufacturers the cost of materials are often high and inflexible, labour is usually done by the business owner/s and theres a storm of unavoidable government taxes, fees and charges that cripple any chance of making a profit so how anyone (apart from the big names) make a dollar in this industry is a mystery.

For me, this is something Ive always wanted to do,I'll make the first run of 50 boards and after that I'll only make as many as are ordered. I can avoid a lot of the government grief if I do this as a non profit hobby so thats my approach, as long as it doesnt send me broke I'll keep making boards.

And if I dont get any orders, you'll find me in the Coolangatta pub.( The Cruel Sea are playing 6th March )

Who is online

Users browsing this forum: No registered users and 44 guests